What to Expect when you visit the Tailor.

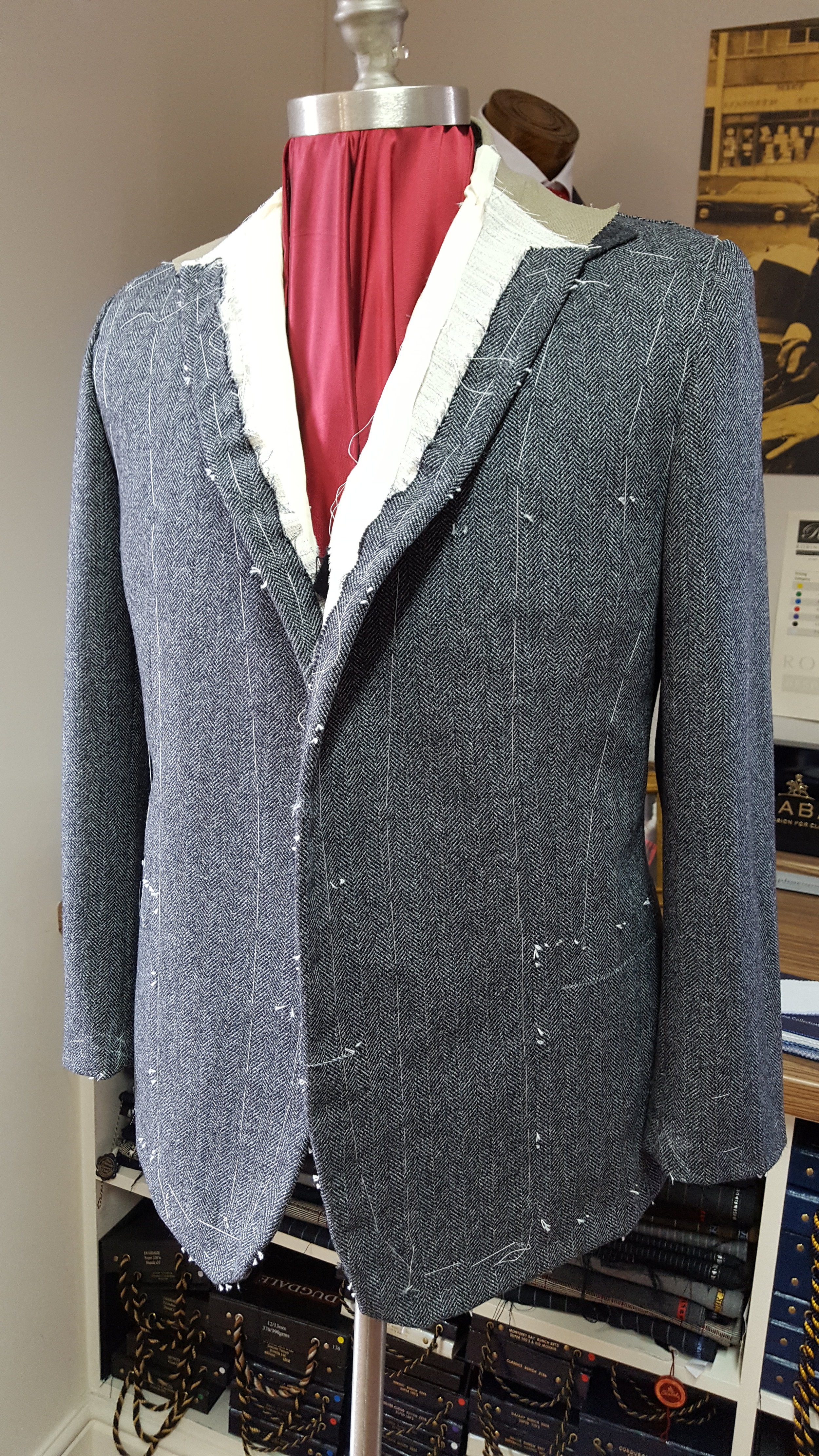

A white jacket in construction. No pricked fingers allowed!

Visiting a Tailor isn’t like going shopping – it’s an experience. But if it’s your first time round, understandably, it can be a little daunting. In our second post we’ll give you a bit of an idea about what to expect.

The following process takes around 6-8 weeks depending on how busy we are! That said we have been known to slot in the odd ‘emergency’ and turn things round in a couple of weeks.

Initial Consulatation

Made to Measure or Handmade Bespoke

o We’ve kicked off with a biggy here. There’s a lot of muddy water involved. For the interest of this blog (we’ll look at Made to measure v Handmade Bespoke another time) we’ll truncate it a little.

o Please allow us to blow our own trumpet briefly. There are not many people who can claim to make ‘all under one roof’ outside of London. Many will want you to believe they do but it’s not the case. Trumpet blown.

o For the purpose of this blog we’ll assume (lucky you) that you’re going down the handmade route as the process is much different to made to measure.

When and where will you be wearing your garment and what for?

o When and where you are wearing your garment makes a big difference to what we’d recommend.

- The climate would dictate the kind of cloth and weight

- The situation – business or pleasure? If you’re commuting maybe you’d want a harder wearing cloth. If you want something for an occasion, maybe something more ‘showy’ that doesn’t have to stand up to everyday punishment.

- Your budget – Our cloth merchants sell some incredible stuff. From your bread and butter worsted to Vicuna via cloth encrusted with diamonds (they blunted our needles!) the base cloth is a big factor when determining the end cost.

o Ultimately this is YOUR SUIT. We’ll always provide our guidance but never stand in the way of your requirements

Measuring

o Exactly what it says on the tin. In a world of computer measurements and plotting our experienced eye and measuring tape is still King

o Wear a suit. And a shirt! It always helps us evaluate what’s what!

End of initial consultation

o At this point we’d work out a schedule of fittings. Typically there would be two but maybe more depending on the customers shape and requirement. We must stress the importance of fittings. It’s a big part of the final result. In the past we’ve been asked, due to time constraints, if they can be overlooked. All we’ll say is that doing so is like going on holiday by bus without looking on Trip Advisor. You’ll get there in the end but you might not be happy with the hotel.

o Deposit Request– Typically 50% of the balance.

A First Fitting or First baste

Second Consultation (2-3 Weeks in)

1st Fitting

o The first fitting gives us a general overview of the fit and ultimately if the customer is comfortable in the garment. Oh, and the balance (how the front and back of the garment align with each other). Usually cut from the finished cloth (unless we have a particularly tricky shape) there’s not much that can’t be altered at ‘first base’ stage. There are no pockets or sleeves at this stage and due to the inlays (extra cloth inside the garment) there’s no need to recut the garment if it needs letting out a touch. The canvas (a term for the chest piece made of Canvas, Domette& Horsehair) is all made and will stay with the garment throughout. There’s plenty of baste stitches (temporary handmade stitches) and, in all fairness, it looks a little raggedy at this stage – but don’t worry we’ll soon sort that.

A second fitting now complete with Sleeve and collar.

Third Consultation (5-6 Weeks in)

2nd Fitting

o By this point we have our pockets in the jacket and the lining is basted in. It’s starting to look like a finished garment. At this point we’ve got a sleeve in. Because people’s arms hang naturally at different angles we may have to alter the ‘sleeve pitch’. It could even be a ‘dummy sleeve’ (cut out of different cloth) if we need to think about matching check alignment. On top of this, how vents hang has to be considered as well as the actual sleeve length. Assuming all your work has been done in your first fit things should be relatively simple, going forward.

What you don't see. The canvas forming the backbone of the jacket.

Collection (6-8 Weeks in)

o Between 2nd fitting and collection we’ll go on to make any minor alterations, fit the sleeves and ‘Finish’ the garment. The Finishing process is another thing that sets apart Handmade from made to measure. Everything is done by hand. Attaching the lining, making the cuffs and sewing the buttonholes. Handmade buttonholes really set a garment apart from one with machine button holes. And then Press. A very important and often overlooked stage. A garment after pressing looks like a completely different garment.

o The customer is all set to collect.

A Jacket with handmade lapel hole ready to go...

A handmade suit takes around 70-80 man hours. It’s a real labour of love for us and something that could last a customer a lifetime (If your garment is made from heavy tweed probably someone else’s too!). What you’re buying into is the best cloth money can buy coupled with over a 100 years of cutting and construction experience in one place. No corners are cut and we aim to make the best garment we can. Every time.